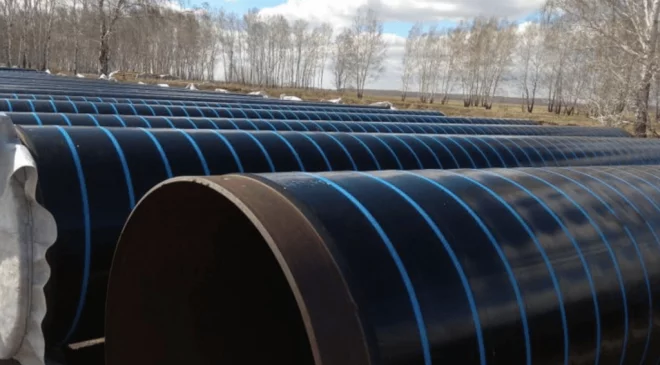

Insulated steel pipes

Insulated steel pipes

Pipes made of insulated steel are ideal for usage in challenging environments. Steel pipes under insulation can successfully operate for several decades, even when subjected to extremely high temperatures, mechanical damage, or chemical agents.

They are frequently utilized in the building of subterranean pipes because of their exceptional resistance to corrosion. Steel pipes have exceptional insulation strength because, as their name implies, they are wrapped in unique layers of insulation.

Insulated steel pipes – characteristics

Three varieties of insulated steel pipes are available from Metal Pipe Industry and Development LLC. These include epoxy-insulated steel pipes, polyethylene 3-LPE-insulated steel pipes, and polypropylene 3-LPP-insulated steel pipes. Steel pipes in insulation can be utilized successfully in projects where the pipe must be bent without worrying about the insulation being damaged thanks to flexible coatings.

Types of insulation offered – anti-corrosion protection on pipes

- three-layer polyethylene insulation – 3LPE according to DIN 30670,

- three-layer polypropylene insulation – 3LPP according to DIN 30678,

- single-layer epoxy insulation – FBE according to DIN 30671,

- bituminous insulation: ZO-1, ZO-2, ZO-3, ZM, WM, WW,

- external insulation on 3LPE, 3LHDPE, 3LPP, and EP pipes according to DIN 30670, DIN 30672, DIN 30678, DIN 30671,

- external anti-corrosion coatings SYNERGY insulation class A50, B50, C50 Standard PN-EN 12 068:2002,

- polyurethane internal and external insulations on PROTEC pipes Execution standard PN-EN ISO 12944; PN-EN 15655:2009 and PN-EN 10290,

- internal epoxy and polyurethane paint coatings,

- internal cement coating on pipes,

- painting external and internal surfaces of pipes

Thanks to the well-chosen and made types of insulation, you will get

- high resistance to mechanical damage,

- resistance to chemical agents, moisture, electrical breakdown, exposure to high temperatures and ultraviolet rays,

- high adhesion of the insulation to the pipe surface,

- anti-corrosion protection of underground pipelines for about 50 years,

- complete protection of steel pipe welds,

- possibility of joining insulated pipes without damaging the insulation,

- the neutrality of the insulation towards the natural environment,

- adhesion to the surface of the steel pipe,

- impact resistance,

- abrasion resistance,

- resistance to indenting force, hardness and stiffness,

- unit resistance of the gas pipeline transition.

The use of steel pipes in insulation

- wastewater and post-treatment water pipelines,

- fuel pipelines in refineries and at petrol stations,

- other industrial pipelines with operating temperatures in the range of -70°C to +50°C,

- drinking water pipelines,

- industrial water and sewage pipelines,

- fuel pipelines, industrial pipelines in refineries, petrol stations and other chemical plants,

- protective pipes,

- pipelines in power plants,

- fire protection pipelines,

- chimneys,

- other industrial pipelines with operating temperatures in the range of -70oC to +600oC,

- gas pipelines,

- pipes for drilling,

- jacking pipes,

- line pipes,

- casing pipes.

We insulate steel pipes in the diameter range from 159 – 2400 m

- pipes 6-16 m long

- longitudinal seam pipes,

- spiral seam pipes,

- seamless pipes.

Our insulations meet all applicable standards, confirmed by:

- coating tightness test

- insulation certificate

- National Institute of Hygiene certificate

- certificates for insulation work